Real-Time Visibility into the Factory Floor

Built-For-You Solutions at Off-The-Shelf Pricing

Get Real-Time Visibility

Cutting-Edge Integration Services

Our team of manufacturing and technology experts will help you create a highly-tailored solution with best-in-class technologies to achieve your business goals and solve operational challenges.

Systems Integration

MES, SCADA, Historians, and more. Our experts will make sure your tech stack is fully functional and delivering maximum value.

Built-For-You MES

Based in Inductive Automation’s Ignition development platform, we’ll build an MES with only the features you want and need, no extra fluff.

Consulting

Not sure where to start? Our manufacturing and tech experts will guide you to create a solution that truly solves your unique challenges.

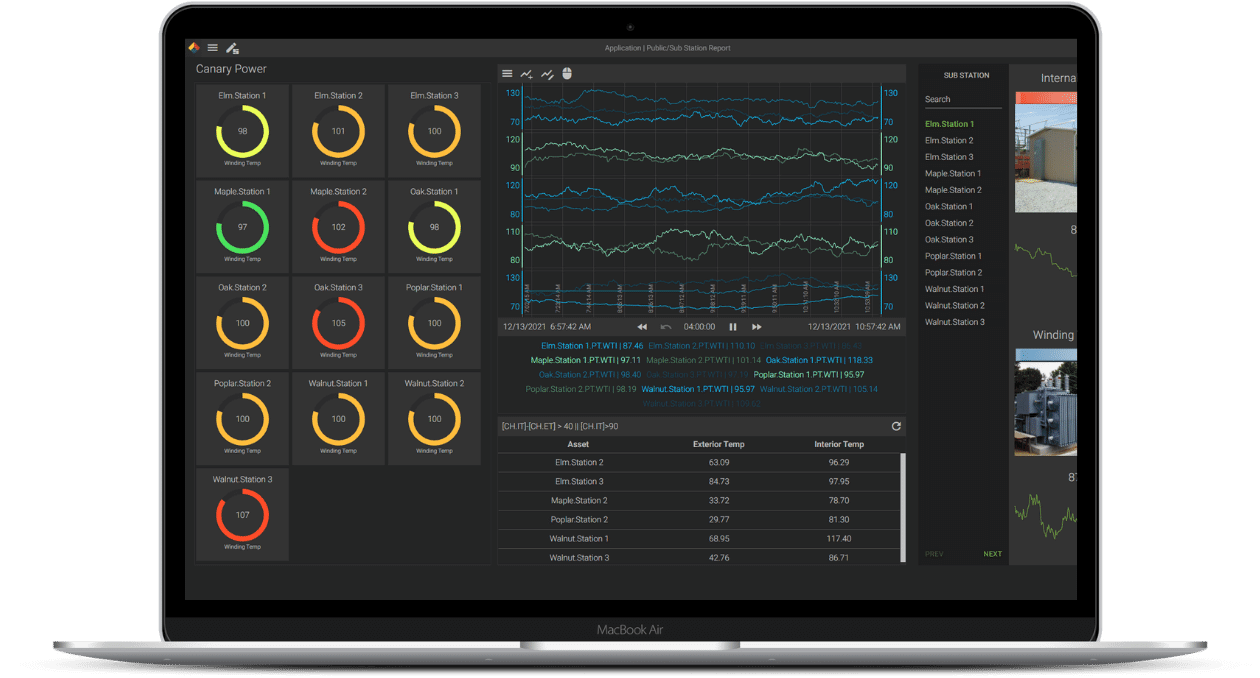

Inform Your Decision-Makers with Reliable Real-Time Data

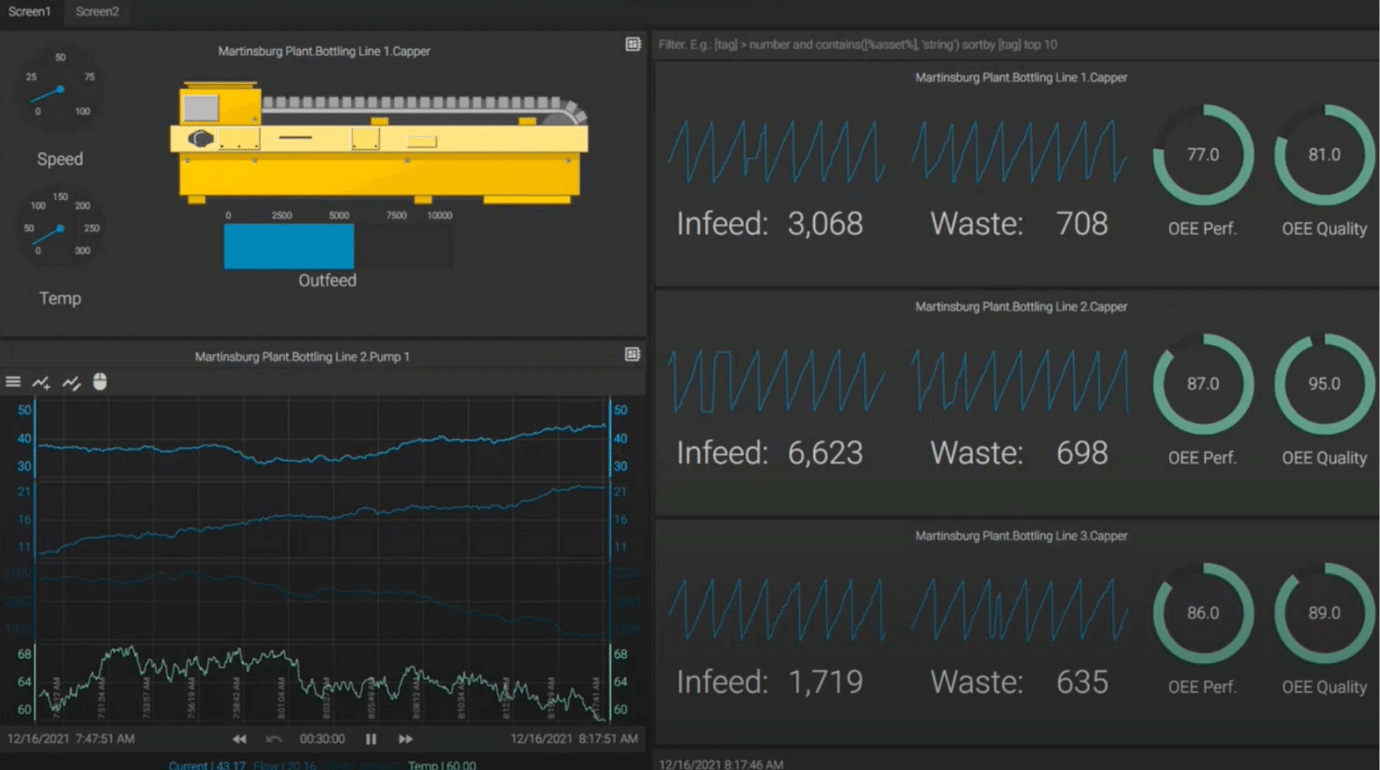

What a Solution May Look Like…

= Your Custom MES, Molded to You, Architected by Experts, For the Price of an Off-The-Shelf Solution

Ectobox is a trusted partner with a track record of providing value and great results for manufacturers on their Industry 4.0 journey. We frequently collaborate with Ectobox on projects because they understand data-driven manufacturing and architectural best practices.

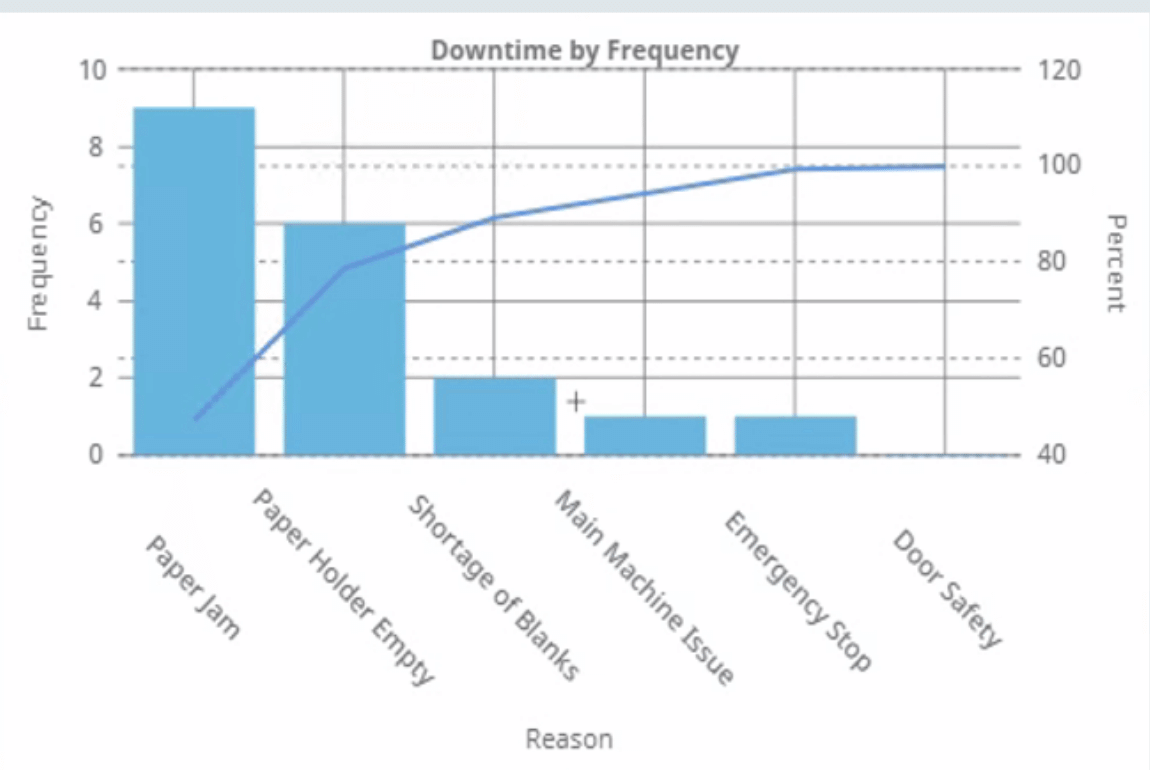

Reduce Machine Downtime

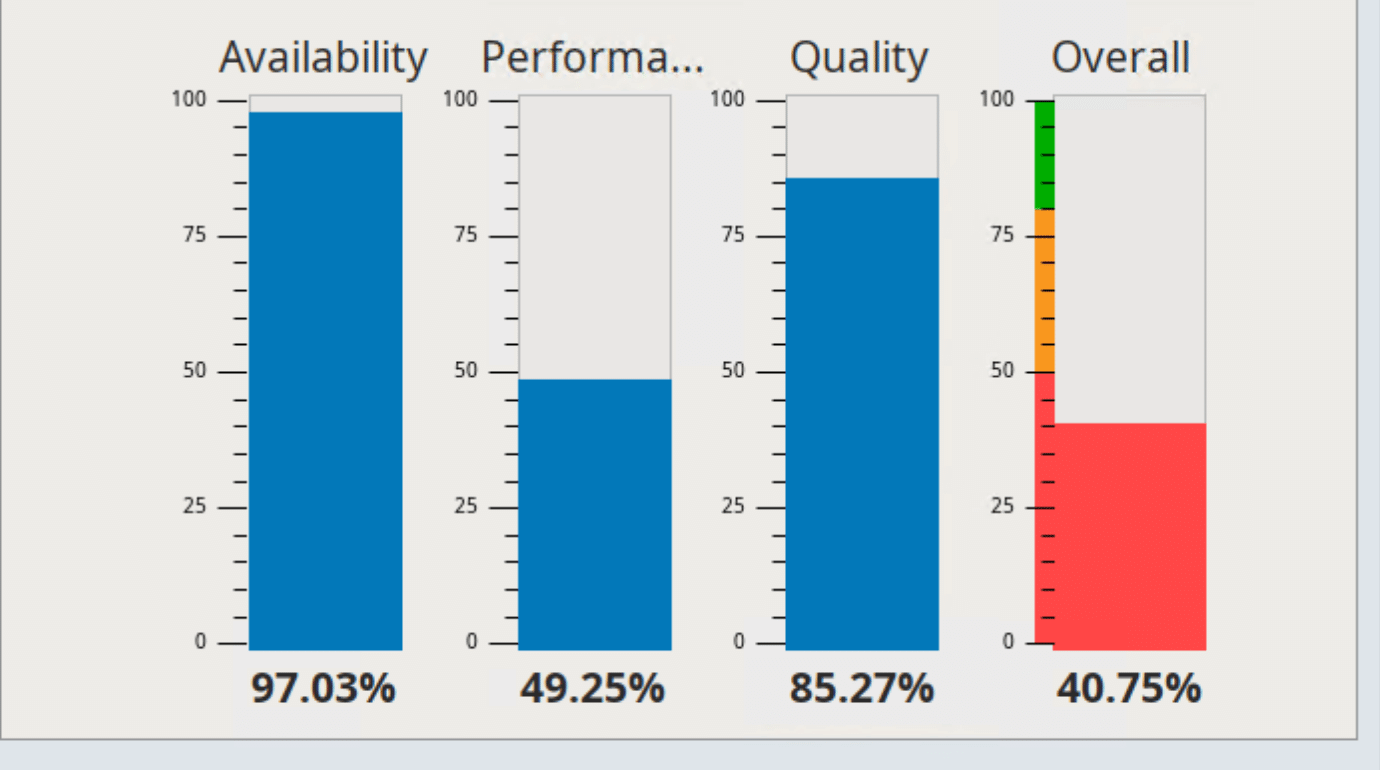

Track and Increase OEE

Eliminate Paper and Spreadsheets on the Factory Floor

Creating solutions that mold to your business, because that’s the way it should be.

Tailored Industry Applications

Medical Device

Chemical

Food & Beverage

Mining

Plastics & Rubber

Precision Metals

Wood Products

Primary Metals

A Dedicated Team of Manufacturing + Technology Experts at Your Side

Our excellent and experienced team of professionals is dedicated to providing exceptional services to our manufacturing clients.

Our team comprises highly skilled engineers, designers, project managers, and technicians who possess vast knowledge and experience in the tech and manufacturing sectors.

We are committed to helping our clients improve their production processes, increase efficiency, reduce downtime, and ultimately enhance their profitability by integrating best-in-class technologies providing real-time plant visibility.

With our expertise and attention to detail, we provide innovative solutions that have earned us a reputation as a trusted partner for manufacturers looking to achieve operational excellence and solve deep-seated challenges.

What Our Customers Say

It is rare that one can partner with such a standout consulting organization like Ectobox. Ectobox ’s ability to balance our business needs with the technical challenges has made a dramatic difference in our overall success. Second to none in honesty and integrity.

HFT has worked with Ectobox for over 20 years. Ectobox has a reliable and well-established staff that can easily take the requirements for a project and turn it into a reality swiftly. Ectobox has helped grow our organization through consistent and industry appropriate solutions.

Data as the New Currency: The Potential of Pharma 4.0

Intro to Pharma 4.0 and facility digitalization Bringing Industry 4.0 to Pharma The pharmaceutical manufacturing industry is undergoing a digital transformation driven by emerging technologies and the need for increased efficiency and innovation. Known as Pharma 4.0,...

Failed Transformations…Learn from Their Mistakes

Many manufacturers have spoken up about past digital projects and initiatives, and why they failed. In fact, I discussed this very topic with a manufacturing client this past week…regarding his conversations with many manufacturers. We summarized the failures he heard about to these three points…the same points that we hear, and Walker Reynolds (from 4.0 Solutions) so often discusses:

Wrong Strategy

Wrong Technologies

Wrong Partner

Should I Care about Industry 4.0 and Why?

Industry 4.0 - The Fourth Industrial Revolution The fourth industrial revolution or Industry 4.0 has been put out here as a panacea, the next easy button in the manufacturing industry to achieve digital smart factories, better production processes, better...

Talk to an Expert

Our MES & manufacturing intelligence experts will address your unique business challenges, answer all of your questions, and make recommendations for you to win by leveraging real-time data!