Industrial Intelligence

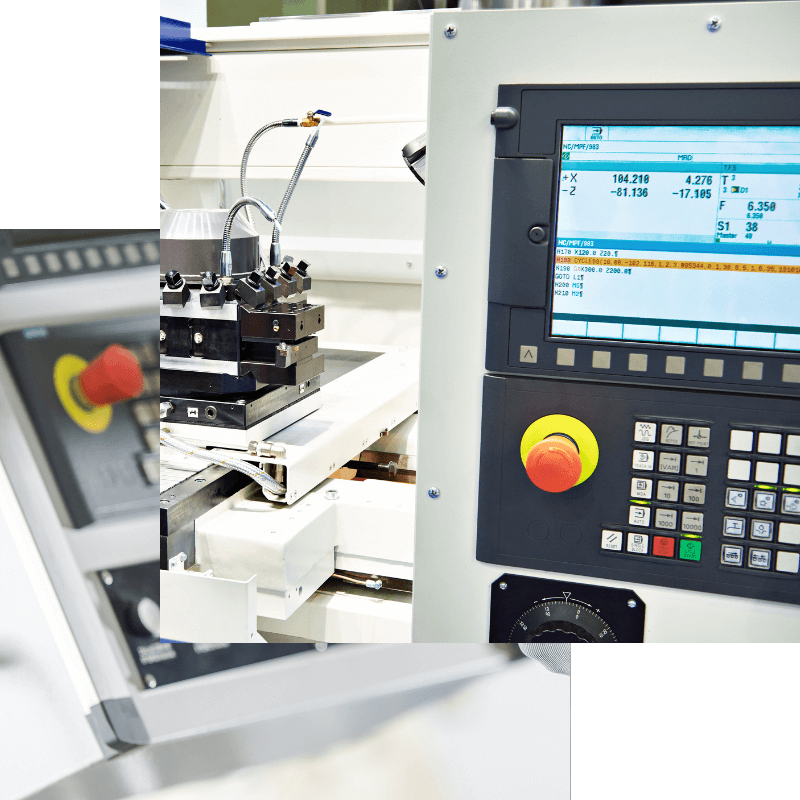

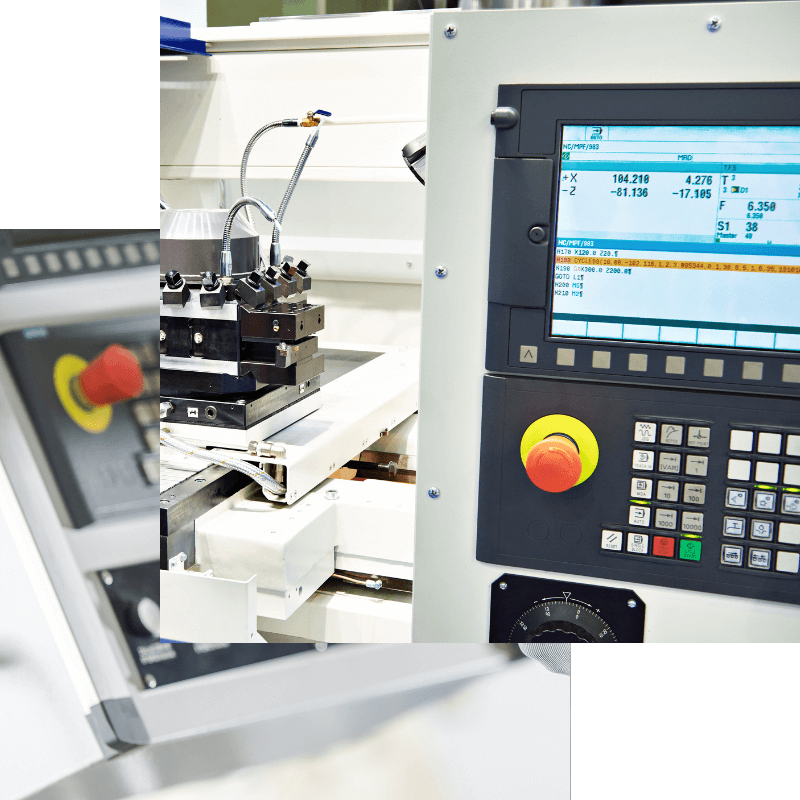

MACHINE SHOPS

Learn how real-time plant floor data can help machine shops solve critical production challenges.

Innovate by Leveraging Actionable Data

Machine shops are highly competitive in the US, and customers are constantly demanding shorter lead times, higher quality, and lower costs.

Despite implementing lean manufacturing, investing in new machines, and hiring more operators, manual data entry errors, machine downtime, and lack of visibility into shop floor operations are still prevalent challenges.

These issues can cause delays, quality issues, and missed deadlines, which can harm profitability and customer satisfaction.

This is where real-time data and a solution such as a Manufacturing Execution System (MES) come in.

Read how this machine shop was able to reduce downtime by 45% on just the pilot project

Unlock Your Hidden Factory

Machine shop manufacturers rely on heavy machinery and equipment that generate a vast amount of data on a daily basis.

However, many lack the solutions to access and analyze this data. By implementing a solution such as a Manufacturing Execution System (MES), you can unlock your hidden factory, full of actionable insights that can guide you in making data-driven decisions to optimize your shop’s performance and profitability.

Reduce Machine Downtime

Improve OEE

Track & Improve Quality

Increase On-Time Delivery

Reduce Scrap

Increase Capacity

solve real business challenges

Which production challenges are relevant to your shop?

An MES or similar solution can help machine shops overcome common production challenges and improve operations.

By monitoring & gaining a better understanding of your production processes in real-time, you can confidently identify inefficiencies & take the necessary action to improve production flow, reduce downtime, and increase productivity.

Jump ahead of the competition and meet the demands of the ever-changing manufacturing landscape with an MES from Ectobox.

I have had the opportunity to work with Ectobox on several projects. They have all been a great experience. Not only do they have the ability to solve many manufacturing problems, but they also do so with tools that scale and extend. The result is a solution that grows with you, requiring minimal investment at each step.

Dive deeper into chemical manufacturing and industrial intelligence

Frequently Asked Questions

How would this fit into what we currently have?

Our solutions can fit greenfield and brownfield situations. What we mean by that is that we can connect to new machines that are just installed on a new network, or with nearly any device or machine that is on a network no matter how new or old the equipment is.

Can a project be done incrementally?

Yes, that’s our preferred method of working on projects. Digital transformation is our strategy, not a single project. Therefore, we prefer to solve challenges one project at a time. We use the Vanilla Scrum project methodology to execute projects. This includes good project planning and requirements definition coming from the waterfall methodology. It also includes an iterative development process with sprint meetings and reviews from the agile development process.

What kind of ROI can we expect from investing in an MES system?

We never work on a project that isn’t going to have ROI. We always evaluate projects for the business problem to solve, the value of that business problem, and ensure that executing the project makes sense. One example is a simple project we did for a chemical company that reaped a 10x ROI in 1 year, which is not unusual for these types of projects.

How do Ectobox projects work?

We follow a logical and best-practice process of Plan, Pilot, Scale. The idea is that one should always:

Plan ahead before taking the first step making sure it’s done right,

- Run a pilot project to confirm the value of the data, confirm the solution works, and

- Scale up the solution from there using the plans and learnings to date.

There is a lot more work and thought that goes into the process. If you want to know more feel free to reach out to have a short conversation.

How does pricing work?

Typical initial projects fall between 30-70k. The pricing depends on a number of factors including whether we’re using off-the-shelf solutions (often less expensive) or building custom solutions, whether we can connect to a software, PLC, or controller; and the type of business challenge(s) we’re trying to solve. Ultimately we find that many of the solutions we create have a full ROI within 3-6 months.

Want to learn more about our solutions for machine shops?

Talk to one of our experts!

Want to book a time with us instantly?

Choose a date & time convenient for you, and our experts will be there.

Talk to an Expert

Our manufacturing intelligence experts will address your unique business challenges, answer all of your questions, and point you in the right direction to win by leveraging real-time data!