*Updated for 2023

Data-driven Manufacturing

Data-driven manufacturing is the act of leveraging data and technology to improve the efficiency, quality, and flexibility of production processes.

The goal of data-driven manufacturing is to use manufacturing data to drive confident decisions resulting in optimized production processes, reduced costs, and increased productivity while improving product quality and meeting customer demands.

Put simply, at its core Data-Driven Manufacturing is about making decisions on manufacturing based on facts, not guesses and opinions. You get that capability of making decisions based on facts by combining 3 things:

- Manufacturing Data Analytics

- IoT

- Data-Driven Culture

Manufacturing Data Analytics

Manufacturing data analytics is collecting, analyzing, and interpreting data from manufacturing processes in order to improve performance & optimize production.

It’s where the data comes from to make educated data-driven decisions.

This data can be collected from various sources such as sensors, production logs, and machines, and then used to monitor and optimize the performance of production lines, predict machine failures, and identify many other production bottlenecks.

Manufacturing Data Analytics Helps You Solve Complex Problems in Your Production Processes

Manufacturing data analytics is a key component that is needed to improve quality, process optimization, and reduce costs by identifying inefficiencies and areas for improvement in the production process.

With the help of advanced analytics and AI, manufacturers can also take advantage of predictive maintenance, improve supply chain efficiency, optimize production schedules, and much more.

IoT & IIoT

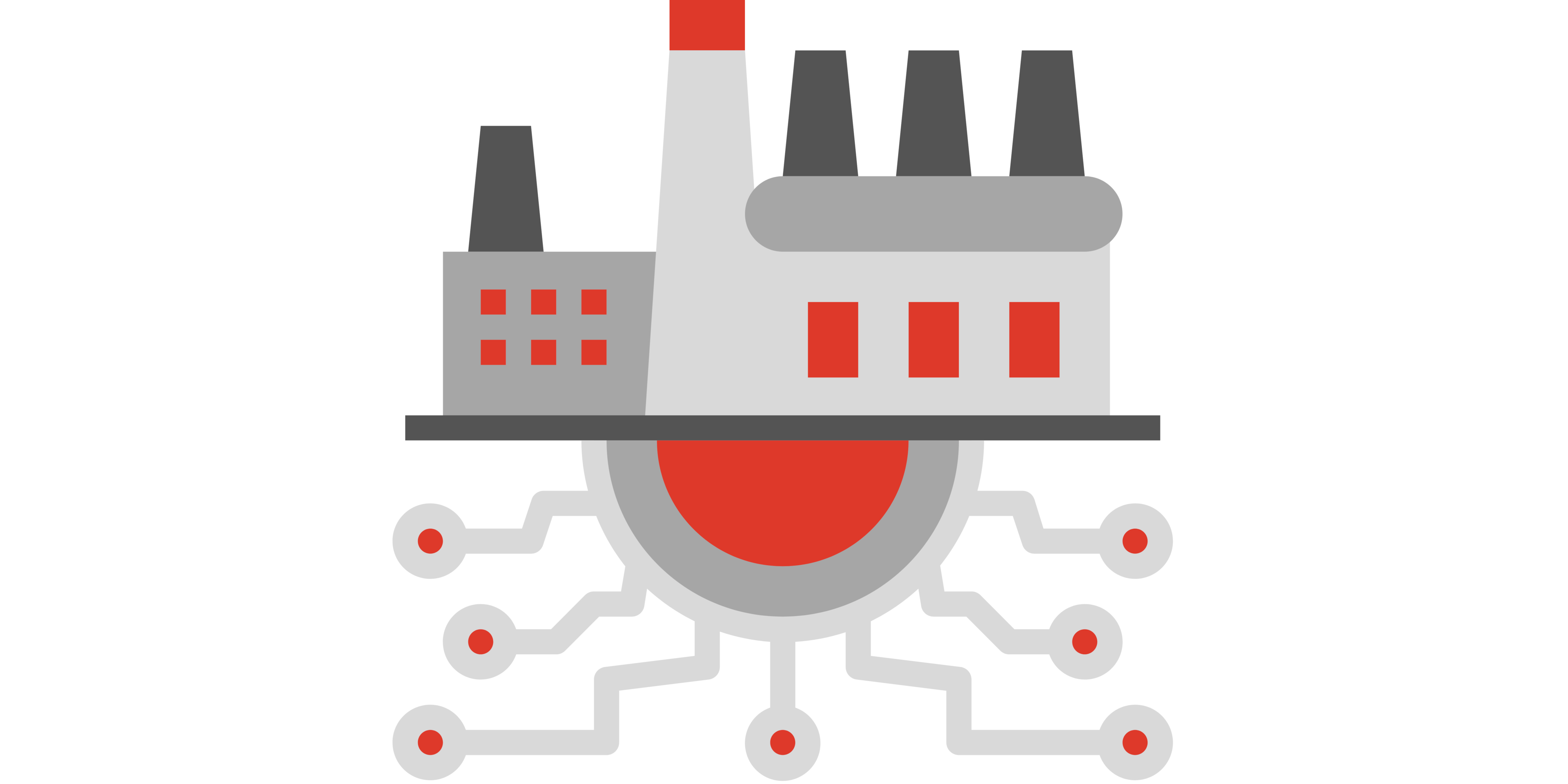

IIoT is the application of Internet of Things (IoT) technology in industrial settings. It involves the integration of connected devices, sensors, and machines that generate data and communicate with each other over a network. The data generated is then transmitted to a centralized platform to be analyzed in real-time. At Ectobox, we like to build around a Unified Namespace architecture.

The collected data from these devices is what can then be analyzed to extract valuable insights that can be used to optimize processes, reduce downtime, and improve decision-making.

IIoT platforms integrate with just about any system used in manufacturing such as enterprise resource planning (ERP) and supply chain management (SCM) systems to provide a complete view of your manufacturing operations.

IIoT Platforms Open the Flood Gates to Data-Driven Manufacturing

The insights derived from this data can be used in near-endless ways to improve operational efficiency. For example, it can be used to predict maintenance needs, identify opportunities for cost savings, optimize energy consumption, and improve production optimization.

Along with these predictive analytics, IIoT also enables remote monitoring and control of industrial equipment, which reduces downtime and increases the overall reliability of manufacturing operations.

IIoT is a rapidly growing trend that is transforming the way manufacturers operate. With the increasing number of connected devices and the increasing availability of manufacturing data analytics and machine learning technologies, the potential for IIoT to improve factory operations is exponential.

Data-Driven Culture

Being Data Driven means that all of the people in the company that require it have access to the right data, can use that data to make decisions, and most importantly are empowered to take valuable action based on that data- Often times corrective or Continuous Improvement actions.

Having a Data-Driven culture at your manufacturing company is growing increasingly important in 2023 and beyond. Still, some companies may not be prepared to take on a Data-Driven Manufacturing solution because they lack a Data-Driven culture.

Manufacturers Need to be Open to Change

People need to be open to change, open to truly improving operations and using data to do it. At some companies, this still isn’t the case. In these cases you’ll often hear, “We’ve been doing it this way for the past 30 years…” and on and on.

That might be the case, but what worked yesterday may not work today. A large number of manufacturers have their own certain way of doing things and have gotten accustomed to using the same process. Without real-time data, it’s tough to find the right areas to focus on and then accurately measure production improvements.

Not too long ago we didn’t have this access to all of the data that we do have access to today. So it was acceptable and common practice to make decisions in a number of different ways, without any of those ways really being based on the data, the facts.

Today, we can gather more data than ever before, and you need to know how to use it to your advantage. Having a data-driven approach is the way to stay competitive. You can completely eliminate guessing on tough decisions and what to do next, even with legacy systems.

Becoming a Data-Driven Manufacturer Doesn’t Need to be a Tough Process

Implementing a data-driven manufacturing system does not have to be an arduous process. Many companies are already using existing data in their Continuous Improvement projects, gathering Lean data, and having daily production meetings. So, they’re already using data.

True Data-Driven Manufacturing simply takes them a couple of steps further…it’s not a leap light years into the future.

Data-Driven Manufacturing simply provides more accurate, additional valuable, and real-time information to use in the existing normal processes of daily production meetings, Lean Manufacturing, Continuous Improvement, etc.

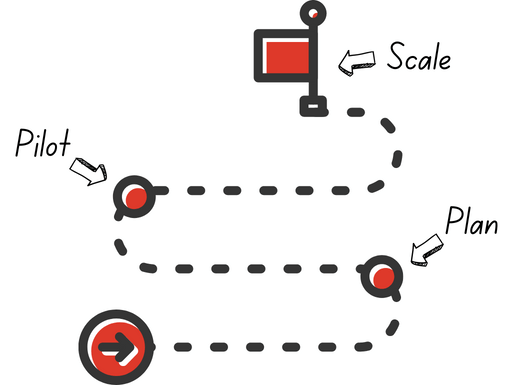

Start small, but think big-

If you want to learn more about our plan, pilot, and scale ideology, check out our dedicated pages under the “our process” tab in the main menu.

Once a solution is in place and used in some of the existing processes and once it’s proven to be really valuable, then the manufacturer can move to expand the Data-Driven Manufacturing solution across more machines, lines, and plants.

How Manufacturers can Establish a Data-Driven Culture

Establishing a data-driven culture in a manufacturing company requires focusing on four key areas: leadership, technology, process, and people.

- Leadership: The leadership team must be fully committed to using data to drive decision-making and must communicate this commitment to all employees. They should also establish clear goals and metrics for data-driven decision-making and allocate resources to support the implementation of a data-driven culture.

- Technology: The company must invest in the right technology infrastructure, including data management systems and analytical tools, to collect, store, and analyze large amounts of data. This includes securing the data, ensuring data quality and governance, and integrating data from various sources.

- Process: The company must establish transparent and efficient data collection, analysis, and decision-making processes. This includes defining roles and responsibilities for data management and ensuring that data is used consistently across the organization.

- People: The company must develop a data-literate workforce that is equipped with the skills and knowledge to use data effectively. This includes training employees in data analysis and interpretation and encouraging a data-driven mindset.

To establish a data-driven culture, it’s important to have a clear understanding of the specific business problems that need to be solved and to identify the data that can be used to address these problems.

Companies must also be prepared to continuously evaluate and refine their data-driven processes as they evolve. By focusing on these four key areas, a manufacturing company can establish a data-driven culture that drives better decision-making, improved efficiency, and increased competitiveness.

Data is Nothing Without Action

Data-Driven Decision Making

Nothing happens, until you take action!

Data-driven decision-making is becoming increasingly important for manufacturers as they strive to remain competitive in a rapidly changing business environment.

This is where your culture starts to play a strong role-don’t implement technology for the sake of technology, make sure the entire company is taking advantage and using it to the fullest.

Some key benefits of data-driven decision-making for manufacturers include:

- No more decisions based solely on guesswork: We touched on this earlier- Data-driven decision-making enables manufacturers to make informed decisions based on data and evidence, rather than intuition or guesswork. This leads to improved performance, numbers don’t lie!

- Increased customer satisfaction: Data-based decision-making also helps manufacturers better understand and meet the needs of their customers, leading to increased customer satisfaction and loyalty.

- Better risk management: By using accurate data to inform risk management decisions, manufacturers can better anticipate and manage risks, leading to increased stability and reduced costs.

In conclusion, data-driven decision-making is critical for manufacturers to remain competitive and achieve their business goals. By leveraging data-driven insights to inform decision-making, manufacturers can improve production efficiency, and achieve better business outcomes.

How The Manufacturing Industry is Adopting a Data-Driven Culture & Digital Transformation

Digital transformation refers to the adoption of digital technologies and processes to improve business outcomes.

The manufacturing industry has been going through a digital transformation during the last few years, driven by advances in technology and the increasing availability of data.

As a result, the industry is moving towards a data-driven culture that leverages data and analytics to inform decision-making.

Some of the key ways the manufacturing industry is adopting digital transformation include:

- Industry 4.0: The industry is embracing Industry 4.0, which refers to the integration of digital technologies, such as the Internet of Things (IoT), and artificial intelligence (AI).

- Cloud computing: The industry is using cloud computing to store, manage, and analyze large amounts of data, and to improve collaboration and communication across supply chains.

- Big Data and Analytics: The industry is leveraging big data and analytics to make data-driven decisions, gain insights into customer behavior and preferences, and improve supply chain and production processes.

In conclusion, the industry is undergoing a significant digital transformation, leveraging digital technologies and processes to improve efficiency, competitiveness, and customer satisfaction. Adopting digital transformation is helping manufacturers remain relevant and competitive in a rapidly changing business environment.

Want to Dive Deeper?

With the definition of Data-Driven Manufacturing covered, and a little extra flavor for how it can fit into a business, let’s talk about the Journey of putting in place and experiencing Data-Driven Manufacturing in our next post.