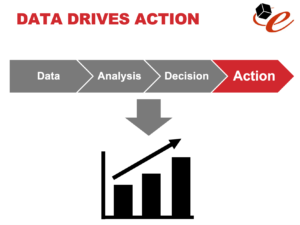

What is a data-driven culture, and data-driven manufacturing? It’s simply gathering, analyzing, making decisions, and acting on data. It’s for companies that have the expectation to be more productive than they were the day before. Going from point A to point B, continually improving, continually setting goals, and being proactive about reaching those goals.

Company success is typically defined in terms of revenue, profits, and evaluation of the company. To improve in these areas, companies need to do more with what they already have. They need to work towards increased efficiency, increased plant floor production, quality control, on-time delivery of products, and they need to meet and exceed customer expectations. To accomplish this you need to be able to find and eliminate inefficiencies, get visibility into the plant floor and understand what’s going on. You need data to understand, and better yet, real-time data.

Data-Driven Culture Simple Breakdown

To have success as a manufacturing company, you need to become a data-driven company and establish a strong data-driven culture among the entire company. There are 3 key aspects to a data-driven culture. These aspects are simple to define but can be tougher to truly implement.

Understand What’s going on

- You need to develop a deep and detailed understanding of what is happening on the plant floor, inside your machines, and in each department of the company. This is your baseline, your starting point, the initial gathering of data and analysis. Everything starts with what you already have so it is essential to know these things very well.

Make Decisions

- Once you have an understanding of what’s going on, you can start to make decisions based on the data you have. Make sure you are making your decisions based on complete and accurate data.

Take Action

- You have a deep understanding of everything happening within the company, and you have made your data-based decision. Now you need to take action based on the decision. Remember the goal is to find and eliminate inefficiencies to drive revenue and profit. You already have the data to find the inefficiencies, now carry out the decision and make the proper adjustments.

In doing these 3 things, you are developing a competitive advantage. You are creating data asymmetry between yourself and the competition, giving yourself the edge.

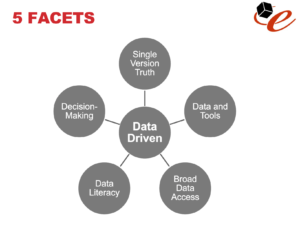

5 Facets to Creating a Data-Driven Culture

1. Single Version of the Truth

- All data needs to come together into one place that is available and acceptable for everyone to analyze and consume. This creates a centralized solution with one version of the truth. No separate databases for different departments inside the company.

2. Data and Tools

- Proper data and tools need to be available for each person within the organization. They should be readily available to any person at any given time.

3. Broad Data Access

- Falling right in line with having proper data and tools, the data itself also needs to be widely accessible for everyone. Everyone should be able to benefit from accurate real-time data. It’s important to ensure everyone will have access when creating a data-driven culture.

4. Data Dictionary

- There needs to be some definition somewhere of what data is being tracked. It should show each data metric that is being gathered. Some type of literature should be made available so that each person will know and understand what data will be available even though not every person will use every single data metric.

5. Decision Making

- People need to understand how to analyze and consume the data, how to review it, and come to a data-based conclusion. Then, be enabled to take action based on that data-driven conclusion.

These are all great characteristics of a data-driven company and principles that company leaders should consider when trying to establish a data-driven culture. But where should you start? There are 4 stages most companies go through on their journey to creating a data-driven culture.

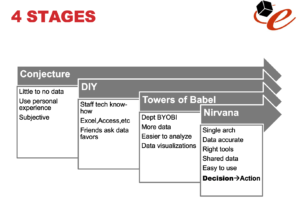

4 Stages to Creating a Data-Driven Culture

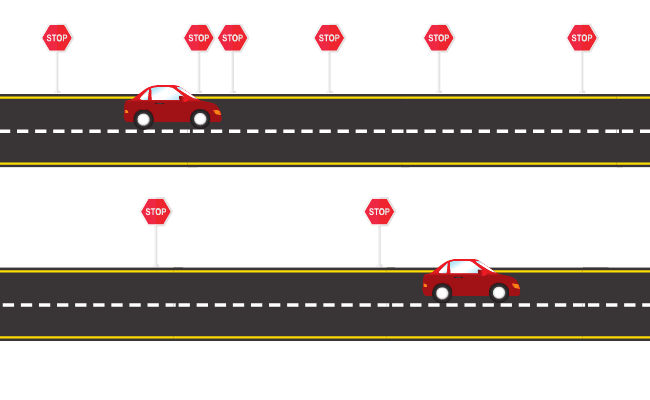

Stage 1. Conjecture

This is when the company has little to no data available to them. Making adjustments and decisions based on past personal experiences- it might be knowledge from a past job, or just a gut feeling. Generally making quick decisions on what to do without much confidence and no real substance backing the decision. Many times they are not very well thought out or consistent conclusions.

Stage 2. DIY

The company is starting to collect data using an excel sheet or similar program. Typically a small database is scattered across the company. You might be recording data manually on paper, or using a whiteboard reporting system. There is a possibility that you are manually sharing data with a handful of people in the company. Many times in this stage, it’s the tech-savvy people who are asked to record, manipulate, and analyze some basic data. Of course, this data will be very limited in detail, accuracy, amount of data, and will often times be old by the time it gets used by a decision-maker.

Stage 3. Towers of Babel

First of all, I love this term, it makes perfect sense. This is when companies are further along in their journey of creating a data-driven culture and truly becoming data-driven. What typically happens in this stage, is the company unintentionally ends up creating numerous silos of data. Each separate department has 1 or 2 primary databases for collecting data. The good news is they are collecting more data, better data, and more systematically.

It’s much easier for the company to get data from these databases as opposed to the DIY stage. Much better for gathering data and getting some basic visualizations. However, it’s a situation of BYOBI (bring your own business intelligence).

This can work for a while but for a company to continue down the path of maturing, growing, driving more revenue, profits, evaluations, etc. These companies need to keep improving and drive even further towards becoming data-driven companies.

Stage 4. Nirvana

In stage 3, companies got their databases to drive data-based decisions with accurate data. So what’s next? Creating a single version of the truth that everyone has access to. The problem with stage 3 is that each department has different data, different data sources. These are all separate solutions, not centralized for everyone. Everyone needs to be on the same page, with the same data. Sales won’t know what marketing is doing, marketing won’t know what operations is doing, operations won’t know what purchasing is doing.

There needs to be one single, full architecture for data with a single version of the truth. A data architecture where all data is consistent and shared between every person and every department of the company. A Unified namespace. This type of solution allows for flexibility and scalability. It is also the most accurate data when it is from one single location and extracted directly from the equipment itself. One centralized database for everyone to make decisions and drive action.

Where to Start

It takes some time and effort to completely transition into becoming a data-driven company. It’s easy to get overwhelmed, and tough to determine where you should start today.

Studies say that analytics pay back $13.01 for each $1 spent. There’s a lot of value in being data-driven, getting started as quickly as possible can be crucial for company success.

A good way to get started on your journey to creating a data-driven culture is to define your own business challenge. Determine where you need the most improvement, and start gathering data. Even if you are just starting with pen and paper. There are stages to becoming a data-driven manufacturer, and you need to start somewhere.

Example

Let’s say that your specific business challenge is not understanding your asset utilization. Not understanding why your machine line or plant overall is not producing as much as you think it should. This is a perfect opportunity to start gathering some basic data. Start now, and try to develop a good understanding of where you are today. How active are your machines? When are the machines off completely? When are they on, but not running? When are they on and running, actually adding value and producing parts?

Gather and analyze that data over time to understand what’s going on. Start capturing downtime reasons- not just that the machine broke, capture the cause of downtime and the machine’s symptoms. Gather data, analyze it, make a decision, and take action. You can look at an asset utilization + downtime reason code Pareto chart to understand what’s going on and what the inefficiencies are.

Conclusion

The above example is a great way to start. The important thing is that you get started, start working towards creating a completely data-driven culture. Use these first small collections of data to help you determine which long-term metrics would benefit you most to keep tracking, and go from there. Start small, think big, and take action.