Industry 4.0 – The Fourth Industrial Revolution

The fourth industrial revolution or Industry 4.0 has been put out here as a panacea, the next easy button in the manufacturing industry to achieve digital smart factories, better production processes, better manufacturing efficiency, increase throughput, leverage automated decision-making, and more. However, what we’ve all seen is a whole lot of hype and limited results.

Let’s cut through the hype. We’ll talk a quick look at some of the definitions out there, talk about what is at the core of those definitions (i.e., its data and information), present an alternate view of Industry 4.0 based on this data focus, and briefly touch on how to work towards achieving Industry 4.0 capabilities.

Hype 4.0

If you were to ask 5 people, “What is Industry 4.0?” you’ll likely get 5 different answers. A short search on Google asking “what is Industry 4.0” returned these results:

“Industry 4.0 refers to a new phase in the Industrial Revolution that focuses heavily on interconnectivity, automation, machine learning, and real-time data. Industry 4.0, which encompasses IIoT and smart manufacturing, marries physical production and operations with smart digital technology, machine learning, and big data to create a more holistic and better-connected ecosystem for companies that focus on manufacturing and supply chain management.” EPICOR – What is Industry 4.0? | Industrial Internet of Things | Epicor U.S.

“Industry 4.0 refers to the ‘smart’ and connected production systems that are designed to sense, predict, and interact with the physical world, so as to make decisions that support production in real-time. UNCTAD – What is ‘Industry 4.0’ and what will it mean for developing countries? | UNCTAD

“Computers are connected and communicate with one another to ultimately make decisions without human involvement. A combination of cyber-physical systems, the Internet of Things and the Internet of Systems make Industry 4.0 possible and the smart factory a reality.” Forbes.com, Bernard Marr – What is Industry 4.0? Here’s A Super Easy Explanation For Anyone (forbes.com)

“The fourth industrial revolution is the cyber-physical transformation of manufacturing. The name is inspired by Germany’s Industrie 4.0, a government initiative to promote connected manufacturing and a digital convergence between industry, businesses and other processes.” TechTarget – What is Industry 4.0? Definition from SearchERP (techtarget.com)

“The realization of the digital transformation of the field, delivering real-time decision making, enhanced productivity, flexibility, and agility.” IBM – What is Industry 4.0 and how does it work? | IBM

One can take any one of those definitions and, depending on how much of a purist you are, claim it as a valid definition.

Each of them differs in a number of ways. However, we see a theme throughout all the definitions. The theme is, “data”, or better yet, “information”. (For the sake of clarity, information is data with context.)

Industry 4.0 For Us

People talk about Industry 4.0 and all the advanced new technologies involved including AI, automation, robotics, big data, remote monitoring, advanced analytics, smart machines, networking, cloud computing, and the list goes on. If you were to draw them all in a circle, what do they all connect to in the center of that circle? What do they all communicate when talking with each other and additional connected devices and systems? It’s Data. For us, data (or information) is at the core of Industry 4.0.

We’ll skip the history lesson of industrial revolutions and simply go with this Industry X.0 moniker for the sake of brevity.

The Third Industrial Revolution

Using that, let’s remind ourselves that the third industrial revolution (Industry 3.0) was the period of computerized manufacturing, thereby automating much of the manufacturing industry processes with that, at the time, new technology. Great strides were made with the ongoing automation of the machines themselves.

Additionally, software was developed to enable control and feedback loops with that automation (e.g., PLCs, HMIs, SCADA, DCS). However, manufacturing technologies didn’t progress sufficiently to connect to and get significant value out of the nascent data in those automation solutions.

The Hidden Factory

Manufacturers need access to more data across their organizations. So much of that data is trapped in the “hidden factory”, PLCs, and more where they produce data every day but can’t access it. More data is also trapped in disconnected siloed software systems, paper documents, and spreadsheets.

Manufacturers need real-time visibility into what’s going on within the factory floor, across the organization, and ultimately up and down the entire supply chain. Where better to start getting that data than from the factory floor?

Manufacturing technology has progressed sufficiently that manufacturers and partners have the capability to get data out of those automation processes, their production process, out of the machines, PLCs, additional sensors, etc.

Let’s also keep in mind that data from a machine is valuable. However, data from a machine with context is so much more valuable. Getting temperatures, pressures, part counts, and scrap counts are great.

Context Matters

But what if you could know what those values were when this or that operator was running the machine, and what part we were running, which shift, on what machine, what were the causes of equipment downtime, reasons for scrap, what were the materials in the product, from what vendors did those products originate, and more? That information (i.e., data with context) has massive value.

Imagine what you can do with that data. You’ll have real-time visibility into what’s going on now and can provide that to frontline workers to solve problems. You can also connect multiple additional systems creating a connected supply chain. Let’s go even further and consider eventually using artificial intelligence and machine learning for data analysis to identify patterns humans can’t see, predictive maintenance, stopping problems before they happen, forecast, and more. These capabilities start to enable manufacturers to automate how the business runs.

That brings us to our definition of Industry 4.0: It is the automation of business processes using the data in those systems. It is all about the Data.

Holy Grail

So, the holy grail becomes the focus of connecting everything and everyone together into a network, then organizing and sharing data across the organization and the supply chain to enable everyone to see what’s going on in real-time at all layers of the organization, and then continue to drive more value from data to accomplish the goals of the company.

What’s Next

We’ve established a high-level, working definition of Industry 4.0. That’s nice. But that definition is worth about as much as the media on which you’re reading this article, i.e., not very much.

How can we get that data and information so we can use it to make better decisions, drive innovation, and most importantly, take action? We can get that value best with a principles-based, strategy-driven approach to Digital Transformation.

Digital Transformation

“Digital Transformation” is another one of those over-used, hype words in the manufacturing industry.

We could come up with some cute alternative like “Digital Evolution” or “Digital Revolution” or something else. It doesn’t matter. The core concept is what matters. That concept is, we need to move manufacturers from the Industry 3.0 mode of operating above (focusing solely on manufacturing automation and running their business with paper, spreadsheets, and a disconnected ERP ((Enterprise Resource Planning))) to Industry 4.0 (fully connected people and systems, with real-time awareness of the business at all levels).

Often companies will approach this transformation effort as a single project or in an ad hoc manner. They’ll also often do so without a fully baked strategy and plan, and no strong organized support from leadership.

Over 70% of Digital Transformations Fail

Many companies will attempt some kind of positive change, or maybe even go through some sort of digital transformation. We too often see the results of failed transformation efforts. Companies create many siloed solutions or connect a few machines with digital technologies, make discrete connections between systems, or use some old paradigms like the Purdue model. The solutions don’t provide the value promised, leaders lose political capital, interest wanes, and digital transformations ultimately fail.

Better Approach…with Industry 4.0

A better approach is to take a top-down and bottom-up strategy.

Top-Down

First, leadership defines and supports a Digital Strategy. This Digital Strategy is a simple statement of how the business will value data, and how to capture and use the value of that data. From the Digital Strategy the company then should be able to work through defining:

Rules and principles around how to make decisions going forward through the transformation including the appropriate new technologies and architectures to use.

Who should be involved in the projects (no CAVE people…Citizens Against Virtually Everything);

How Digital Transformation projects should be run….a mix of waterfall and Agile (i.e., a mix of two project management styles);

Roadmap of a series of projects to execute to connect, collect, store, analyze, and visualize data to digitally transform the organization; and

The first use case to execute- Where you put in place the new technology and architecture.

Two other key areas are the Minimum technical requirements and the Unified Namespace.

Minimum Technical Requirements (MTR)

Edge Driven – Data is pushed or published from the edge (machines, PLCs) in one direction; there is no poll-response;

Report by Exception – Data is reported only when it changes; there is no poll-response;

Light Weight – Communication technologies & protocols with a smaller footprint (e.g., smaller message headers) so the messages consume fewer network resources; and

Open Architecture – Collected data is openly accessible to other systems and published and consumed using industry-standard messaging formats.

The Minimum Technical Requirements remind manufacturers to select technologies that are more flexible and scalable than the alternatives. A good example is the MQTT communication standard with the Sparkplug B specification. It uses an event-driven, publish-subscribe concept allowing all systems to publish real-time data to a central location.

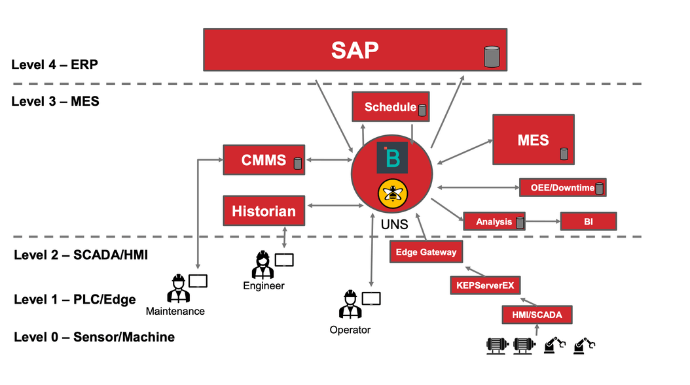

The Unified Namespace

The Unified Namespace (UNS) is also very valuable as a concept and architecture. The Unified Namespace takes the publish-subscribe idea with an MQTT data broker and then adds a data model to use for organizing the data reported into the system for contextual data analysis. Specifically, the ISA 95 Part 2 standard of Enterprise/Site/Area/Line/Cell is used for structuring all of the data.

The Unified Namespace then becomes the single point of access for all data collection in real-time across an organization…not only machine or telemetry data but also data from across business systems…making it a valuable “single source of the truth” for the entire organization.

Then Bottom-Up

Once the Digital Strategy is set, and rules for selecting technologies and architecture are defined, then it’s time to get the architecture, technologies, and solutions in place for the frontline workforce to access the data, innovate, improve the manufacturing processes, and improve overall operations.

A Key Component to Success – Choosing The Right Partner

Therefore, the manufacturer should partner with a vendor/partner that is comfortable with the strategy and approaches above. This means that the systems integrators that have close ties to major technology suppliers which provide proprietary, vendor lock-in approaches are not a good option. Additionally, the integrators that take the single-project approach to put in a single-technology, solution-centric platform are also suspect.

Once the Digital Strategy is in place with the other pieces (MTR and UNS) it’s time to get the solution in place. Generally, the process is

Architect the specific solution,

Get the network connectivity in place if it isn’t already,

Connect the machines,

Develop the solution: typically a small MES with a few basic capabilities such as OEE, downtime with reasons, and work order management,

Test and commission

Train the frontline workforce on how to use the solution (typically is straightforward),

Measure the ROI.

All of those steps are critical, including measuring the ROI. It should be measured so the plant and partner teams that put the solution in place can determine if it was valuable, and where to focus next if it was. Solutions have been put in place for far less than $1M and have provided a manyfold return simply by accurately calculating basic operational KPIs like OEE, providing downtime and quality with reason codes in real-time, and enabling the frontline workforce to act on the data.

After the Initial Project

After these solutions are extended within the first work cell, machine, or line, they are often scaled up to the rest of the plant and enterprise. The technologies and architectures can also provide the same real-time access to the data across the whole enterprise and are open for integration across the supply chain as well over time.

Summary

The flexible, scalable IIoT (Industrial Internet of Things) ecosystem enables open access to data and information across the enterprise and supply chain. This then becomes the definition of Industry 4.0…automating business processes using the data from across the enterprise and supply chain.