Executive Summary

Many small manufacturers struggle with successful Lean efforts. Often the cause is bad data. Industrial IoT solutions can drive improvements in Lean efforts by providing accurate, real-time data. The data comes from remotely monitoring production, scrap, equipment downtime, processes, and waste in the production system with Industrial IoT solutions. Manufacturing staff can then closely monitor the systems over the short term to determine if the Lean efforts were effective and the long term to ensure the issues don’t return.

Value Stream Maps and Kata’s are specific tools often used in Lean efforts to identify and eliminate waste. These Lean tools use metrics to measure and reduce waste. Data from the Industrial IoT solutions can feed the data for these metrics. Using Industrial IoT as the source of the data provides accurate, real-time data which enables successful Lean efforts and compounds the positive results. Additionally, Industrial IoT saves significant time for recording and analyzing data compared to gathering data manually.

Introduction

Are your Lean efforts as effective as they could be? Where do you get data to identify and monitor the impact of your Lean efforts in your factory? The answers to these questions can have a significant effect on the ROI of your Lean efforts. The best results of Lean work come from having accurate, real-time data. Without it, your results will suffer.

Accurate Data is Important

I’m sure you remember the essence of Lean is to reduce waste in your plant. People are often surprised to hear the statistic that nearly 80% – 95% of all activities in producing your products for your customers are non-value-add, especially in high-mix/low-volume plants. That means there is a significant amount of wasted motion, transportation, waiting, and more going on in your plant.

This waste can come in multiple forms: waiting and non-utilized talent of the operators during unplanned machine downtime due to machine breakdowns, overproduction of parts as a machine processes the part more than is needed, transportation as people and tools are moved around more than required, machine downtime due to longer change-overs which could be reduced, excess inventory piling up in front of a workstation, or excess inventory of spare parts for maintaining machines due to reactive maintenance practices, and more.

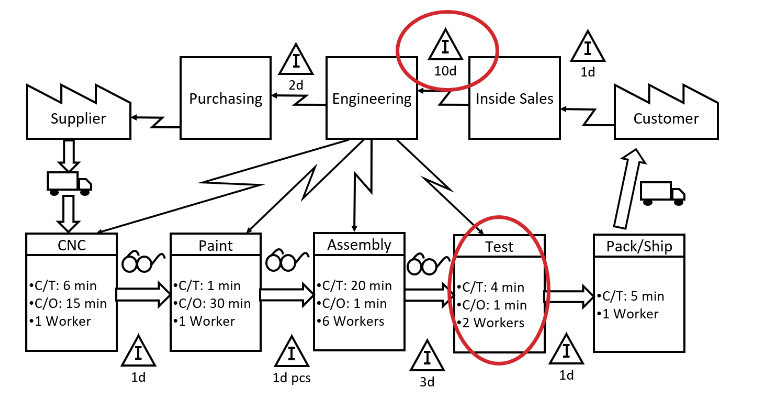

What is your process to identify that waste? One way to identify waste in terms of Lean is to create a Value Stream Map of your plant’s current operations and a Value Stream Map of your plant’s preferred future state. Creating the Value Stream map includes gathering data about the manufacturing processes, like cycle time, takt time, uptime, planned downtime, unplanned downtime, production lead time, processing time, transportation time, production counts, and other values. Users of the Value Stream Map then review the details to identify where waste is and how it can be reduced or eliminated.

The key to finding non-value-add activities in your plant is the data. Those values are captured on the Value Stream Map like cycle time, wait time, transportation time, and so forth. Everyone knows the expression “garbage in, garbage out.” It applies well in this situation. Suppose the data gathered and placed into the Value Stream Map isn’t accurate. In that case, the Value Stream Map user may incorrectly identify a source of waste or misapply resources to reduce a given non-value-add activity.

Case Study

To truly understand the impact of no data or bad data when reducing waste with Lean efforts, think about a situation in your plant. Let’s say we have a foundry manufacturer with a finishing area. They are a high-mix, low-volume manufacturer. The finishing area has presses and CNC machines. There are parts in a job that pass through several machines in sequence in the finishing area. Each machine performs a different task and has different cycle times. Currently, operators are recording production for each job and overall machine downtime on paper at the end of a shift. The company is so busy handling issues that it’s rare the shift supervisory or production manager has time to hand-enter data into an Excel file for analysis. It is also likely that maybe a couple of operators might be writing down data that may not be entirely accurate. The only reliable data that exists is the number of products packed at the end of the line.

In this situation, we don’t have much data to work with, only some basic spreadsheets with incomplete and possibly inaccurate data. Therefore, it’s difficult to identify what operators are working efficiently, what kind of wait times exist, is the machine downtime due to change-overs optimal, and whether there any issues with machines causing problems and resulting in unplanned downtime, etc.

What data should we get to measure? It’s hard to say until we use a Value Stream map to tell us, which we’ll do below. When creating the Value Stream Map, we’ll find there are two stages where we need to gather data: 1) at the point when we’re creating the Value Stream Map, and 2) on an on-going basis to confirm the Lean work has produced good results and those results continue.

Industrial IoT Turbocharge

For the example above, how will we gather and compile that data? You’ve already seen the challenge: operators have a job to produce parts, not be data entry clerks. So, entering data is not a priority for them. Additionally, entering the data by operators and compiling the data by others is a form of waste. It could be considered excess processing and non-utilized talent, if not more. It also creates an issue because the data is often incomplete and inaccurate. This means garbage in, garbage out in terms of results and value from the data.

If instead, we were able to automatically gather data from machines, operators, and other systems without manual intervention by anyone, we would get data directly from the machine and the data would be available immediately; the data would be accurate and real-time. This data will then provide clear visibility into what is going on the factory floor. This process of gathering data from the plant floor is where Industrial IoT comes into play.

What is Industrial IoT

What is the Industrial IoT (Internet of Things)? IoT is the process of pulling data from sensors on devices like machines in a manufacturing plant, pulling that data over a network, converting that data to valuable information, and then presenting that data to people to make decisions and, most importantly, take valuable action based on that information.

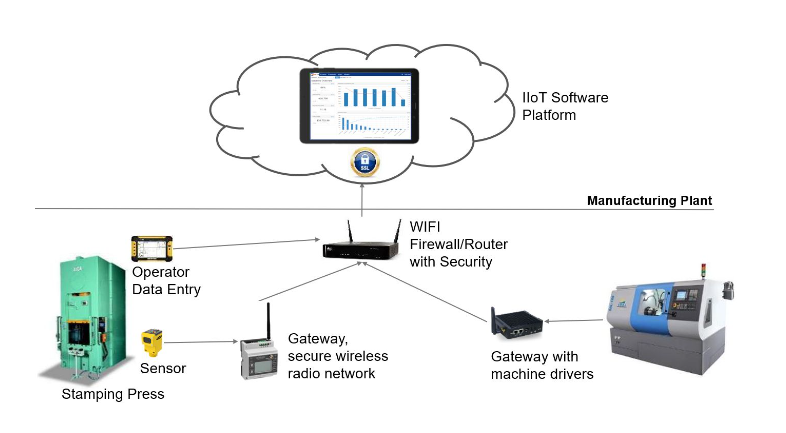

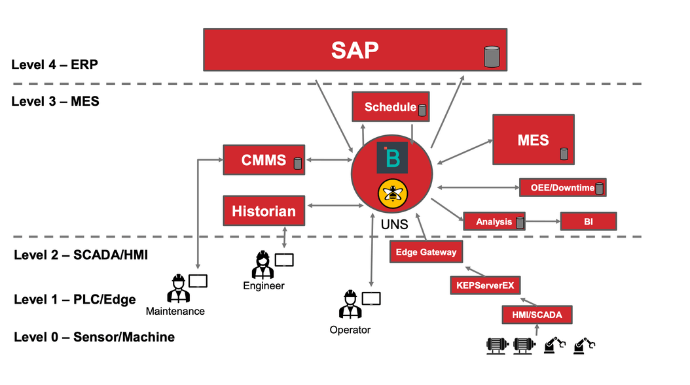

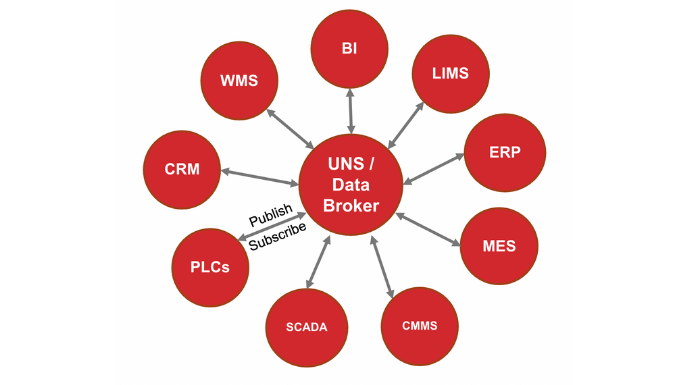

Industrial IoT solutions are typically made of a set of sensors, a gateway or edge device, a network, a software platform, and a set of security protocols and tools to ensure all data at rest and motion is secure. The sensors will communicate with the gateway/edge device, and the data is then sent to the software platform (aka, Industrial IoT platform). The data is often processed, filtered, and analyzed in the edge device and more commonly in the Industrial IoT platform. That platform is also where manufacturing staff view and analyze the data on a variety of devices. For legacy equipment, the sensors are added to the existing machine. For newer equipment, there may be sensors and a software system inside the machine (e.g., a controller in a CNC), or a PLC with sensors. In these situations, the gateway/edge device is connected to the newer piece of equipment or PLC, and the data is pulled, translated from the existing data protocol, and then sent on to the Industrial IoT platform.

The structure of an Industrial IoT solution above sounds complex. It turns out it does take some experience setting up these solutions, but it is by no means rocket science; it is also a straightforward solution. The types of tools, sensors, IoT gateways, and other devices that exist today make each project a repeatable solution, not a new science project for every situation. Additionally, highly experienced Industrial IoT engineers and project managers, along with an approach to solve business challenges first rather than technical challenges, are key to successful implementations.

One of the issues we have seen with small and mid-sized manufacturers is a fear of projects going out of control and costing hundreds of thousands of dollars to get any kind of reasonable data and a return on investment. This is undoubtedly not the case. The approach of working on a problem incrementally and starting with a pilot project for a Lean effort can limit risk and increase the ROI of the Lean effort. Pilot projects for Lean efforts can typically be put in place within a couple of days or a couple of weeks and cost a lot less than you might think.

3 Examples of Lean with IIoT

Let’s get back to our case study above, the foundry manufacturer with a finishing area. We’ll review how accurate data can significantly impact Value Stream mapping for identifying and monitoring wastes in a Lean project.

Visual Stream Maps

“Value stream mapping is a lean manufacturing or lean enterprise technique used to document, analyze, and improve the flow of information or materials required to produce a product or service for a customer.” (ref.iSixSigma.com) Value Stream maps are a stepping stone to lead into various Lean techniques that fall under the Continuous Improvement umbrella. It enables the transition into the various Lean techniques because the resulting map clearly defines how the shop floor currently operates, no matter how well or how poorly. Value stream maps can also be used to define a preferred, future state shop floor operation. It can establish a clear goal of how the shop should be running after the issues identified in the current state map are addressed.

The definition of a Value Stream map includes references to the flow of information. This reference is a direct indication that data is a vital part of Value Stream Maps. Data in the Value Stream map provides context on the manufacturing process; where there are delays, where data is gathered manually, how many times a part is processed, where the parts are moved, etc. In other words, it is an important tool for identifying wastes in the manufacturing process.

When reviewing a high-level Value Stream map like the map above, you can see the data points to gather cycle times, change over times when there is planned downtime, wait times, production, number of people per shift, etc. These values are used in the example in this post. You can also display first-pass yields, quality, scrap, reliability, expediting costs, and more. This data is collected using Industrial IoT solutions. Once collected, the Lean team can monitor the data after changes are made to the processes. This way the team can ensure the changes were valuable and then continue to monitor and improve the systems over time.

Let’s return to the foundry with the finishing area example above. Documenting the manufacturing process in a Value Stream map with current data would be a valuable exercise. This will provide valuable insights such as finding that parts typically pile up in front of a certain machine which happens to have a faster cycle time. Before creating the Value Stream map the inventory piling up may not have been a concern, possibly because they figured the piles didn’t site long due to the faster cycle times. However, additional data was added to the map which indicated the machine has long changeover times creating a lot of machine downtime and lost opportunities for production. The Lean team might then realize that if they worked to dig deeper into the changeovers they may discover some waste they could eliminate and vastly decrease the changeover times and related machine downtime. If successful, there would be a cascading effect that reduces the inventory and thereby increases asset utilization, production throughput, and revenue for that machine.

Other Examples

Here are a couple of real-world examples of manufacturers using Lean to identify and reduce waste with Value Stream Maps. These case studies are good examples of how accurate and real-time data provide big impacts when combined with Lean efforts.

Case Study 1

Here’s a situation we heard about recently which underscores the impact of using Industrial IoT with Lean. Additionally, the manufacturer identified the issue from a Value Stream mapping effort. This large manufacturer produces huge machines. Those machines were, in fact, train engines (i.e., locomotives). The challenge was forms of waste resulting from the distance between the shop producing engines and the shop of repair technicians. The repair technicians had to walk a long distance to get to new locomotives about to come off the line that required servicing. When the technician arrived at the engine, there’d be a list of work to be done. If the technician didn’t have the tools and parts required, they’d have to go back to their area, get the right tools and parts, and come back. This caused issues with downtime of the crew assembling the engines and last-minute scrambling to reassign them during that production downtime. What wastes can be found in this situation? The three easiest to identify are transportation, waiting, and non-utilized talent. This particular issue was one of several around the plant.

Early on, the Lean/continuous improvement team couldn’t clearly identify this as an issue until they had some data from a Value Stream mapping effort. Once the data about transportation and waiting were captured “on paper,” it became clear this was a big issue. It quickly became clear that the best solution was to pull production and quality data for the engine from an Industrial IoT solution and provide each engine’s data to the technicians. They can then review the quality issues that exist from their shop, determine the parts and tools required, and go the long distance to the engine in question prepared for the work at hand. This access to accurate, real-time data resulted in eliminating nearly all the wastes identified, improving the production throughput, and reducing production costs.

Case Study 2

A manufacturer experienced issues with on-time delivery and was a mid-sized manufacturer with high-mix, relatively low-volume production (i.e., they produced highly customized parts in medium to low volumes). The engineering team’s customizations included work to modify drawings, confirm they are correct, and send them through a set of approvals. Part of the leadership team in engineering took on the challenge to solve the issue.

One of the first efforts was to create a high-level Value Stream map to document product and data flow. It started at the beginning, which included the sales team. Documenting the process was straightforward. Once the first version (without data) was completed, it was nearly impossible to see where the waste issues existed. Some effort was put into identifying part counts, cycle times, wait times, etc. As soon as the numbers were added to the Value Stream map one of the major issues quickly became self-evident. There was a ten-day wait time for orders from sales to get into the engineering department for processing. It turns out that sales wouldn’t request the right drawings and other detailed information from the customers. When engineering would get an incomplete order, they would push it back to sales or sit on it without notifying sales that the order was incomplete. Once accurate data was available in the Value Stream Map, the issue was quickly identified.

The company then created a custom ECN (Engineering Change Notification) software product created by Ectobox. Once implemented, the engineering leader monitored the improvements in wait times and throughput for his engineering department. The data also helped identify where they could make many additional improvements in processes to reduce the wait times, further increase throughput, and ultimately significantly impact on-time delivery to the customer.