My point is, data comes from many different sources, different solutions, and can be gathered and analyzed in many different ways with each technique having its own pros and cons. Today, we are going to talk about a simple 2 step solution that depending on how you choose to approach it, could be planned out and started within a day.

There are 2 major steps to improving machine setups:

- Gather and visualize data from the machine during the setups;

- Review the data with the operator to get insights into what they’re doing.

Simple right? Almost too simple, let me explain more about how one might go about executing these 2 steps.

Every machine shop and precision metals manufacturer is always looking for ways to increase production, reduce scrap, and overall improve manufacturing efficiency (or at least they should be). As a discrete manufacturer with a large number of product changeovers- one area that can always use some attention is the setup of machines. Setups are among the most difficult work one can do in a machine shop.

The Impact Machine Setups have on Overall Manufacturing Efficiency

Improving machine setup procedures increases quality and production on each job. Many shops will have only a few operators that are exceptionally good at the setup work. These few operators prove how efficient machine setup can be. You need to capture and take advantage of their process and experience.

Many times, we see that these operators are asked to handle all of the setups.

Instead of just accepting that one person knows how to tackle a certain situation better than another, why not find out why and use it as training for the other willing and capable operators? If one person can accomplish a process effectively, so can your other operators. Start gathering and analyzing data from your top employees, determine why they are better, and make that part of the training.

2 Ways To Attain the Information You Need

How do you capture their knowledge and best practices? There are two options, both can get the job done.

One is much easier to get started quickly and for cheap, while the other will take more upfront time and money, but is a much more scalable and viable long-term solution.

1. In-Person Observation

The first option is directly observing the operator in person while they perform their setup tasks and take written notes. This method is difficult and many details can be missed. It is also very time-consuming. Therefore, the value and potential for success with this process is limited.

However, this option requires essentially zero upfront money and very little preparation time. You can give it a shot today and take a step towards becoming a truly data-driven manufacturer.

2. Capture Data & Review with Operator

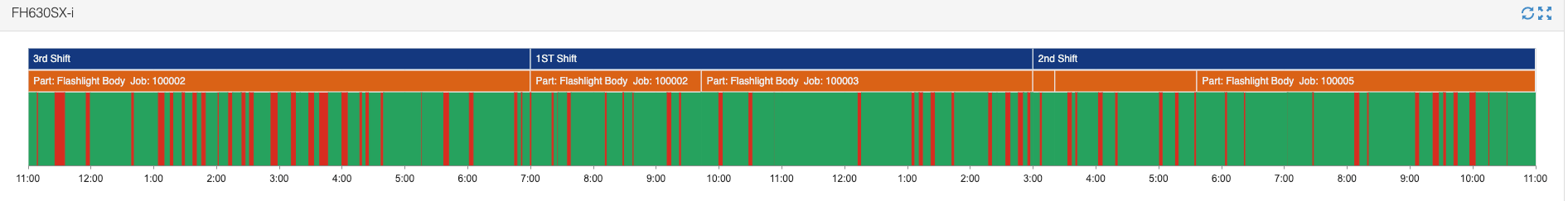

The second option starts with gathering and visualizing data directly from the machine while the operator is performing the setup. A good data chart is a timeline of events and activities from the machine. That chart, combined with a focused conversation with the operator, can provide some key insights.

An operations leader can pick out certain patterns in the data and discuss those with the operator. The operator can then explain exactly what they were doing at that time. During this conversation, the operations leader may find practices that make the process more efficient or yield better results than other operators. Those practices can then be codified and taught to other operators.

The process of using data and reviewing with the operator provides more accurate and valuable insights in less time than direct observation and note-taking.

What’s Next?

Now we know what we need to do and why. For the remaining parts of this article, we are going to put ourselves in this situation, and make an example of how this type of solution might work. Furthermore, we will see how much of a difference tracking this process can make, and the potential improvement on your overall manufacturing efficiency.

Setting the Scene

In this theoretical situation, here are the details we’re working with:

- We are a Precision Metals Company that Creates Machine Tools

- Have High-Mix, Low-Volume Production

- Vertical machining, CNC lathes, horizontal machines, mill-turns, and grinders

- The focus is to keep the machine shop as productive as possible

Capture and Visualize Data from the Machine

In this situation, we are going to go with the second option that does not require constant manual data entry. Remember that this is a very simple solution. All you need is a program that can collect very basic data, a full-blown MES or IIoT solution is not necessarily required.

The first step is to connect to the machine. Potentially using a relatively universal CNC communication standard like MTConnect or the very common FOCUS2 protocol for FANUC controllers.

Gather and store the following data:

- Machine’s Mode (Manual or Automatic)

- Status (Running or Stopped)

- Program Run Time with the Program Number that is Running

- Part Count

Once connected record the data for one job that will run, even if it’s for a few days. Be sure to start recording the data before the operator starts the setup process.

Create a timeline view. It’s possible to use some basic data visualization tools too.

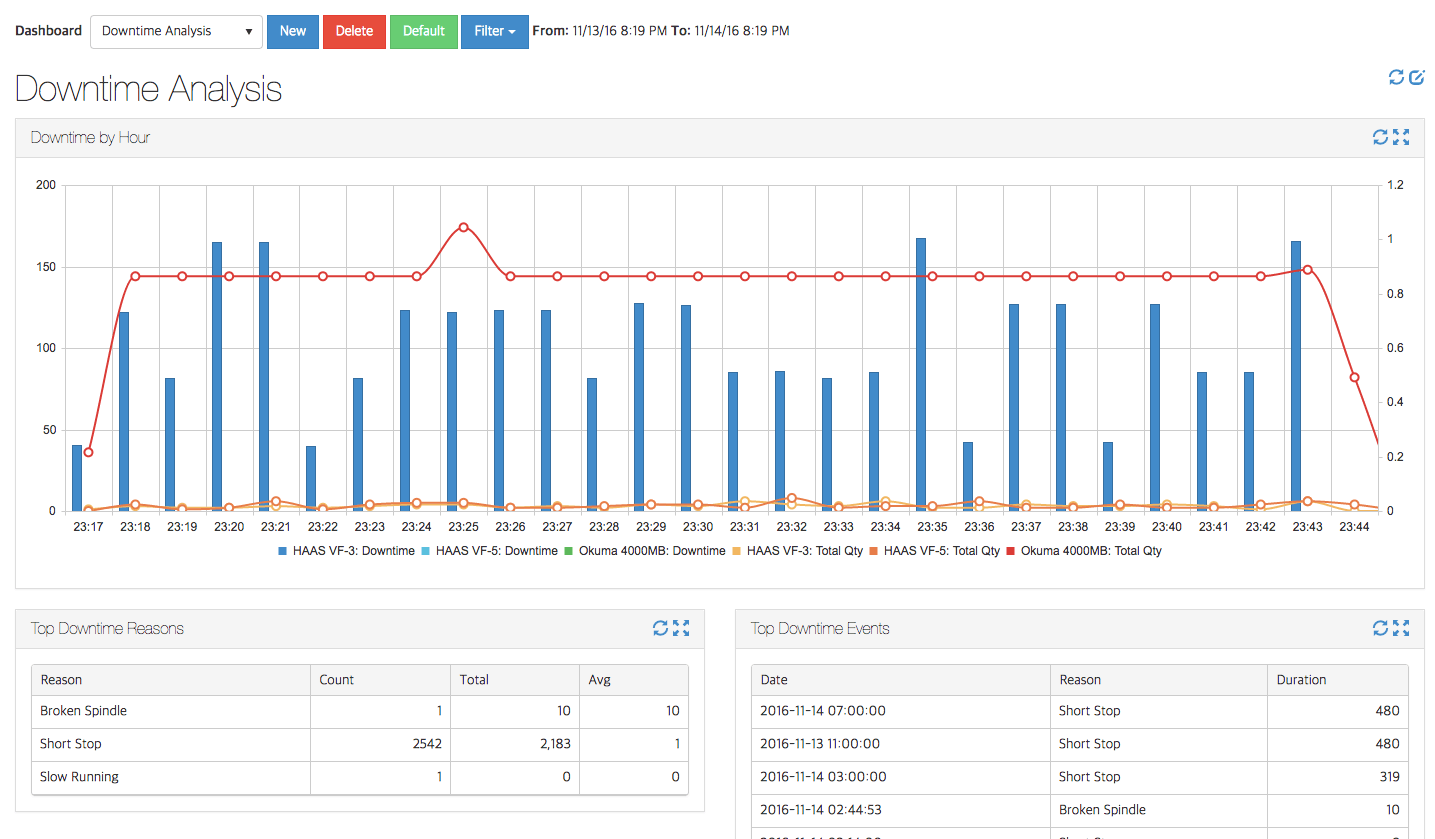

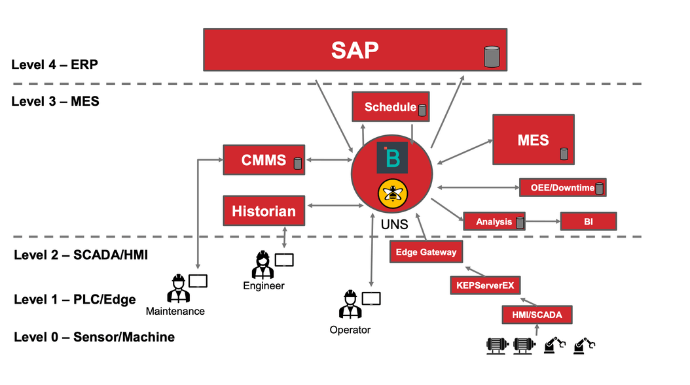

Sometimes we also use OTF (off-the-shelf) products that can connect to nearly any machine and visualize any of the machine’s data in timeline charts. In addition, these platforms provide downtime reason codes, analysis, and much more valuable data that you can gather from the plant floor. Although the information that these platforms provides is extremely valuable, for this example we will stick to the basics.

An interesting point is that for this example, the data can be raw from the machine. There is no additional contextual data needed. We most often work with additional contextual data because it significantly extends the value of the machine data. However, in this situation, the only contextual data we need is the dates/times and the job being run.

Review with the Operator

An operations leader, such as a production supervisor or someone higher up in the chain, should review the results. This person should be closely familiar with the machines and tools.

The operations leader should then review the operator’s activities in the timeline chart with the operator present. The operator can explain exactly what he was doing for particular events in the timeline. The combination of data from the machine as well as input from the operator with the data in front of them is the combination that will provide the best results possible.

The best setup operators are very efficient with their work. Their tools are well organized, they are effective in how they use their instruments for measurement, execute their procedures correctly and thoroughly, and they perform their work with a sense of urgency.

Capture insights and Start Improving Manufacturing Efficiency

One example of where the review of information turns out to be valuable could be focusing on multiple starts and stops during the setup.

After a review of the timeline and some discussions, the operations leader should be able to determine that the operator was performing stop checks to ensure the cutting tools would be within tolerance limits before the job was started. This process ensures the parts will be within spec while the job is running.

The visualization could reveal that the operator was loading new tools into the turret and sections of the machine required for the job that would run for a few days. While loading each tool he was using a micrometer or caliper to check feature dimensions. This would ensure the parts produced would be within required tolerances.

What You’re Left With, and How Manufacturing Efficiency Will Get Improved

The value of the timeline along with the operator’s explanations was:

- Have an objective source of information on the operator’s activities.

- Have accurate measurements of those activities (how long they took) and their sequence.

- Zooming in and out of the timeline to change the perspective; and

- Have data on the production run after the setup to confirm the quality of the setup, during normal shift hours and in “lights-out” production hours.

The alternative to using a timeline with accurate, objective data on the operator’s activities is to visually observe the operator in real-time and takedown written notes. The operator of choice’s work is likely so smooth and well done that the details are difficult to observe. Furthermore, even more difficult to accurately capture in writing while they’re performed.

This diligent setup work done at the beginning of the job will reduce the time the operator needs to monitor and adjust the machine during the job which enables him to run more machines and jobs at once. This efficiency then decreases the downtime while the job is running and increases production.

Conclusion

As a quick summary- Gather basic data, basically just time-stamps detailing when the machine was and wasn’t producing, analyze your top-performing employee’s tendencies, and make an example out of them.

This is a great way to get your foot in the door and get started along your data-driven manufacturing journey. Once you implement a solution and strategy similar to this, you can prove to yourself just how valuable data can be to improve manufacturing processes.

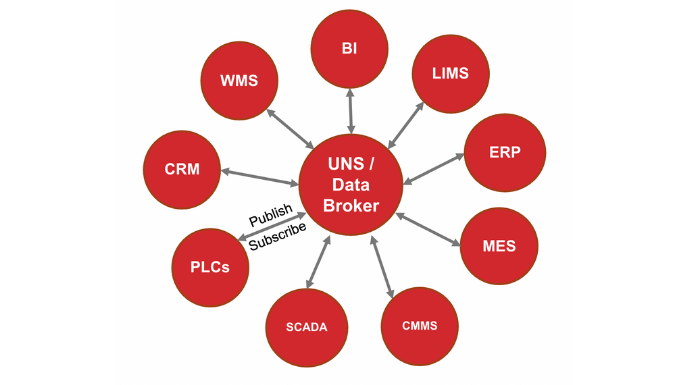

In time you can scale the solution. Once you find that your machine setup times and manufacturing efficiency have greatly improved, you can move on to a different process or metric to start tracking.

Scaling the solution is of course great. It means you have made great progress and found a lot of value in the data. Implementing a solution equipped with real-time data, contextual data, numerous reporting features, and the ability to communicate with other systems can bring a lot to the table. However, what is really important is that you get started with data-driven manufacturing, and develop and stick to a strong strategy with clear goals.