The Manufacturing Execution System That Connects To Everything Without Vendor Lock-In

In this review, you’ll learn more about and be better equipped to handle your most critical plant floor inefficiencies, how to get a quick win with real-time data & minimum investment, and how your competitors have approached similar situations.

Sign Up To Book Your Free Manufacturing Efficiency Review!

Our Industry 4.0 & manufacturing intelligence experts will address your unique business challenges and discuss potential solutions to win by leveraging real-time data!

Ectobox is a trusted partner with a track record of providing value and great results for manufacturers on their Industry 4.0 journey. We frequently collaborate with Ectobox on projects because they understand data-driven manufacturing and architectural best practices.

A Sneak Peek Into What Our Free Manufacturing Efficiency Review Looks Like

Sounds interesting right? Book your free review today and we’ll help you get the right tools and technologies in place to improve efficiency and reach your unique business’ goals.

Find Out if Your Business Is A Good Fit

We don’t create solutions for the sake of technology. Our experts will ensure that you’re a good fit and that there are real production challenges that can be solved with data.

Learn How To Solve Critical Plant Floor Challenges

Tell us about your most critical production challenges on the plant floor, and we’ll help point you in the right direction based on our past experience in helping manufacturers operate more efficiently.

Learn How Real-Time Data Improves Efficiency

We’ll get into your unique challenges and provide specific use cases relative to how you could leverage real-time data to reduce downtime, increase OEE, maintain compliance, and much more.

How You Can Get A Quick Win With Data

Our Industry 4.0 & manufacturing intelligence experts will address your unique business challenges and discuss potential solutions to get a quick win leveraging real-time data!

Industry 4.0 & Data-Driven Manufacturing

Learn about emerging software and our agile approach to implementing real-time visibility into the plant floor, because manufacturers should strive to become data-driven and compete not on labor costs, but on innovation and quality.

What Your Competitors Have Done

Learn how your manufacturing peers and competitors have approached and solved similar challenges.

Projects

Satisfied Clients

Ongoing Projects

Cups Of Coffee

It is rare that one can partner with such a standout consulting organization like Ectobox. Ectobox ’s ability to balance our business needs with the technical challenges has made a dramatic difference in our overall success. Second to none in honesty and integrity.

HFT has worked with Ectobox for over 20 years. Ectobox has a reliable and well-established staff that can easily take the requirements for a project and turn it into a reality swiftly. Ectobox has helped grow our organization through consistent and industry appropriate solutions.

How does pricing work?

The pricing depends on a number of factors including:

- Whether we’re using off-the-shelf solutions (often less expensive) or building custom solutions,

- Whether we can connect to software, a PLC, or a controller;

- And the type of business challenge(s) we’re trying to solve.

Ultimately we find that many of the solutions we create have a full ROI within 3-6 months.

What does Ectobox do?

Ectobox is an Industrial Intelligence Solutions company. We help manufacturers operate more efficiently and grow.

We do that by connecting manufacturing machines, people, and data systems, pulling the data together into a single data hub, and providing that data to people on the plant floor and across the company as needed so they can get real-time visibility into the plant floor and the company.

Another way of saying it is that we are an IIoT / MES (Manufacturing Execution Systems) integrator, implementing off-the-shelf and custom IIoT and MES solutions for manufacturers in North America.

How do Ectobox projects work?

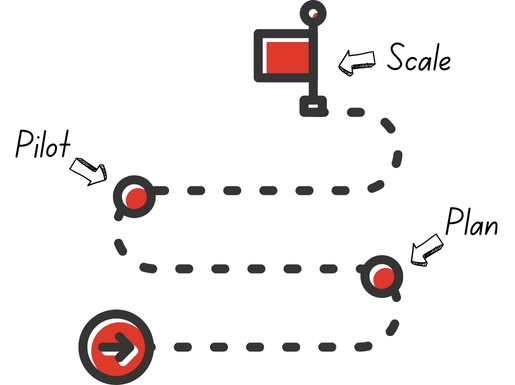

We follow a logical and best-practice process of Plan, Pilot, and Scale. The idea is that one should always:

- Plan ahead before taking the first step to make sure it’s done right,

- Run a pilot project to confirm the value of the data, confirm the solution works, and

- Scale up the solution from there using the plans and learnings to date.

There is a lot more work and thought that goes into the process. If you want to know more feel free to reach out to have a conversation!